|

|

| | |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

All rights reserved:Anhui

Yinli Numerically-controlled Machine Tool Trading Co., Ltd (all

rights reserved, no transport allowed) Copyright 2015-2018 Anhui

ICP Record No. 17001465-1

|

|

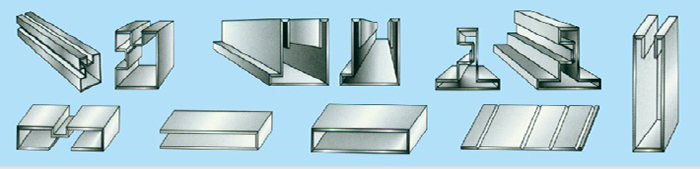

Yinli Company-specialize

in sales of plate shears, bending machine, rolling machine, press,

leveling production line, air duct production, section bending,

wrapping machine and metal processing equipment, etc.

|