|

|

|

|

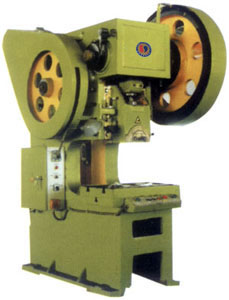

J23/J21S Mechanical Punch

|

Structure and Characteristics

J23 series of punch is ordinary open-type inclinable press,

whose structure is simple and convenient to operate, with

reliable performance. Rigid twist-key type clutch can

be used, whose use and maintenance is convenient. Emergency

braking device can be fitted to enable the slider to emergency

stop during 0 to 135 degrees and the photo-electric protector

can be equipped as well. J23-125 uses iron cast machine

body, the crank shaft longitudinally set, eccentric locking

collar structure forming is adjustable, pneumatic friction

clutch, so that is work is stable and impact small, the

slider can stop at any position. |

|

Main

Technical Parameters of J23 Mechanical Punch

|

Model

|

J23-16

|

J23-25

|

J23-40

|

J23-63

|

J23-80

|

J23-100

|

J23-125

|

J23-200

|

J23-250

|

|

Nominal Pressure

(KN)

|

160

|

250

|

40

|

630

|

800

|

1000

|

1250

|

2000

|

2500

|

|

Slider Journey

(mm)

|

50

|

70

|

80

|

80

|

100

|

100

|

140

|

145

|

145

|

|

Slider Strokes

Per Minute min-1

|

110

|

65

|

50

|

50

|

50

|

40

|

38

|

38

|

38

|

|

Maximum Shut

Height

|

170

|

200

|

220

|

250

|

270

|

300

|

370

|

420

|

410

|

|

Die Adjustment

(mm)

|

30

|

30

|

45

|

50

|

60

|

80

|

100

|

100

|

100

|

|

Distance

from Center of Slider to Machine Body (mm)

|

160

|

200

|

220

|

250

|

260

|

310

|

395

|

400

|

400

|

|

Size of Workbench

(front to back*left to right) mm

|

320×460

|

350×520

|

390×630

|

420×650

|

470×750

|

570×860

|

740×1150

|

780×1250

|

780×1300

|

|

Size of Shank

Hole

(Diameter*Depth) mm

|

Φ40×60

|

Φ40×60

|

Φ50×70

|

Φ50×70

|

Φ60×80

|

Φ60×80

|

Φ60×85

|

Φ60×85

|

Φ60×85

|

|

Thickness

of Workbench mm

|

45

|

50

|

70

|

70

|

80

|

80

|

100

|

120

|

130

|

|

Size of Slider

Undersurface(front to back*left to right) mm

|

120×180

|

170×220

|

210×250

|

240×280

|

260×300

|

360×400

|

360×430

|

410×500

|

410×500

|

|

Motor Power

kw

|

1.5

|

3

|

4

|

5.5

|

5.5

|

7.5

|

11

|

15

|

15

|

|

Overall Dimensions

(Length*Width*Height) mm

|

|

1120×860×

2200

|

1600×1100×

2250

|

1740×1100×

2250

|

1765×1265×

2650

|

1940×1490×

2850

|

2350×1780×

3600

|

2540×2010×

3800

|

2740×2280×

3580

|

|

Net Weight

kg

|

1090

|

2100

|

2960

|

3800

|

5015

|

6120

|

14500

|

18000

|

20000

|

J21s series of press machine is gap

press with fixed bed whose depth of throat is increased, with lark

work space and extensively used in punching of sheets of difference

sizes.

The machine body uses steel plate welding, with very high strength

and rigidity. Rigid twist-key type clutch is used for convenient operation

and maintenance. Emergency stop device is optional for fitting, which

enables the slider to emergency stop from 0 to 135 degrees. J21S-100

and 160 use crank shaft longitudinally set structure, pneumatic friction

clutch, hexahedron rectangular guide rod and upper lifting type pneumatic

balance device, convenient for match with various pressing and peripheral

equipment, belonging to deep-neck series of high-end machine type.

|

Model

|

J21S-25

|

J21S-40

|

J21S-63

|

J21S-80

|

J21S-100

|

J21S-160

|

|

Nominal Pressure

(KN)

|

250

|

400

|

630

|

800

|

1000

|

1600

|

|

Slider Journey

(mm)

|

70

|

80

|

80

|

100

|

100

|

160

|

|

Slider Strokes

Per Minute min-1

|

70

|

50

|

50

|

50

|

40

|

50

|

|

Maximum Shut

Height

|

200

|

220

|

250

|

270

|

300

|

500

|

|

Die Adjustment

(mm)

|

30

|

40

|

50

|

60

|

80

|

110

|

|

Distance

from Center of Slider to Machine Body (mm)

|

710

|

710

|

710

|

800

|

800

|

950

|

|

Size of Workbench

(front to back*left to right) mm

|

400×600

|

420×650

|

440×670

|

470×750

|

570×860

|

740×1300

|

|

Size of Shank

Hole

(Diameter*Depth) mm

|

40×60

|

50×70

|

50×70

|

60×80

|

60×80

|

65×90

|

|

Thickness

of Workbench mm

|

50

|

70

|

70

|

80

|

80

|

110

|

|

Size of Slider

Undersurface(front to back*left to right) mm

|

170×220

|

210×250

|

240×280

|

260×300

|

360×400

|

800×1300

|

|

Motor Power

kw

|

3

|

4

|

5.5

|

5.5

|

7.5

|

15

|

|

Overall Dimensions

(Length*Width*Height) mm

|

1620×800

×1950

|

1730×1100

×2300

|

1980×1100

×2290

|

2260×1265

×2450

|

2230×1490

×2700

|

2200×1545

×3530

|

|

Net Weight

kg

|

2100

|

3210

|

3210

|

5800

|

7020

|

15500

|

|