Performance

Characteristics:

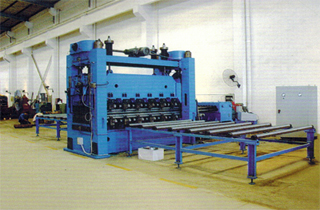

W43 series of roll-type leveling machine is a

cold leveling machine for metal sheets and strips.

It can make the surface of processed sheets and

stripes even, smooth and flat. It's extensively

used in metallurgy, ship manufacture, boiler,

metal structure, electrical appliances and machine

manufacturing industries.

According to the different arrangement of levelling

machine's roll system, we mainly divide them into

the following modes, which are described as below:

un-parallel roll layout levelling machine, with

the upper roll fitted on inclinable movable cross

beam, and the inclination can be adjusted based

on requirements. This type of leveling machine

can make the bending deformation grow small, able

to guarantee levelling quality, and it's convenient

to adjust. Therefore, it's extensively used in

leveling thin plate and middle plate.

Parallel roll layout leveling machine: major feature

is that the movable cross beam lifts at the same

time with upper work roll and two sides' guide

rolls, and the guide roll can also be independently

lifted. It can feed at both sides and repeatedly

leveling, applicable to leveling of thick plate

or high-strength plate.

Conventional type of leveling machine: can meet

ordinary customers' requirements, and most commonly

used. Since there is no special processing requirement,

the cost is low, it can be called economical leveling

machine.

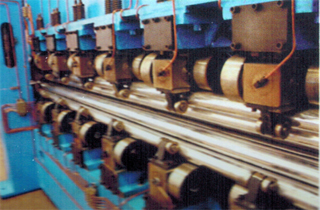

Six-roll leveling machine: used in leveling of

stainless steel, duplex metal, steel plate with

surface coated or plated and non-ferrous metal

plate. It can maintain smooth surface, to avoid

the impact of indention on the plate produced

by support roll of ordinary four-roll leveling

machine.

The whole frame of all the above machine types

are frame-style, with high strength and good rigidity.

Control system can use ordinary mode, digital

display mode or PLC CNC mode, meeting different

special requirements of users.

|

|

|

Type

|

Max.calibration

thickness (mm)

|

Calibration

width of plate(mm)

|

Roller

quantity

|

Roller

dia (mm)

|

Roller

dia center distance(mm)

|

Plate

calibration speed (m/min)

|

Accuracy(mm)

|

Main

motor power (KW)

|

|

3×300

|

3

|

300

|

11

|

72

|

80

|

7.5

|

≤1.5

|

2.2

|

|

3×500

|

3

|

500

|

11

|

72

|

80

|

7.5

|

≤1.5

|

3

|

|

3×1250

|

3

|

1250

|

13

|

115

|

120

|

9

|

≤2

|

15

|

|

3×1500

|

3

|

1500

|

13

|

115

|

120

|

9

|

≤2

|

18.5

|

|

6×1600

|

6

|

1600

|

13

|

135

|

145

|

11

|

≤2

|

22

|

|

6×2000

|

6

|

2000

|

13

|

150

|

156

|

11

|

≤2

|

22

|

|

8×2000

|

8

|

2000

|

9

|

180

|

190

|

10

|

≤2

|

22

|

|

8×2500

|

8

|

2500

|

9

|

220

|

230

|

10

|

≤2

|

30

|

|

10×2000

|

10

|

2000

|

9

|

220

|

230

|

9

|

≤2

|

30

|

|

10×2500

|

10

|

2500

|

9

|

240

|

250

|

9

|

≤2

|

37

|

|

12×2000

|

12

|

2000

|

9

|

240

|

250

|

9

|

≤2

|

37

|

|

12×2500

|

12

|

2500

|

9

|

260

|

270

|

8.5

|

≤2

|

45

|

|

16×2000

|

16

|

2000

|

9

|

260

|

270

|

8.5

|

≤2

|

45

|

|

16×2500

|

16

|

2500

|

9

|

280

|

295

|

8.5

|

≤2

|

55

|

|

20×2000

|

20

|

2000

|

9

|

280

|

295

|

8

|

≤2

|

55

|

|

20×2500

|

20

|

2500

|

9

|

300

|

315

|

8

|

≤2

|

55

|

|

25×2000

|

25

|

2000

|

9

|

300

|

315

|

7.5

|

≤2

|

55

|

|

25×2500

|

25

|

2500

|

9

|

340

|

355

|

8

|

≤2

|

75

|

|

30×2500

|

30

|

2500

|

9

|

380

|

400

|

7

|

≤2

|

90

|

|

30×3000

|

30

|

3000

|

9

|

380

|

400

|

7

|

≤2

|

90

|

|

|