|

Performance

Characteristics:

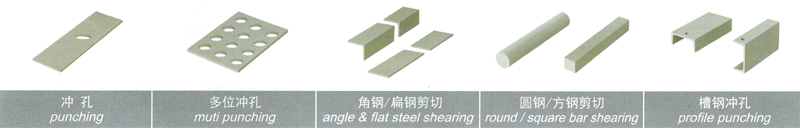

Using hydraulic transmission, it's the newest product

of combination of punching and shearing machine in domestic

China for now, able to shear, punch shear and die shear

square steel, round steel, angle steel, flat steel, groove

steel and joist steel. The body of this machine composes

of body, engine base, steel stents, angle steel support

and shearing workbench. The machine body and base are

steel plate welding structure, other parts are linked

by bolts, which ensures the strength and rigidity during

work as well as convenience for maintenance, installation

and dismantling.

The right wallboard of the body is fitted with adjustable

heel block, which restricts the shuffling of cutting board.

The angle steel support has adjustable pressing device,

which presses the angle steel tightly for shearing.

The steel stent has rectangular and round holes of different

sizes, so that the rectangular and round steel can smoothly

pass through to carry out shearing.

There is adjustable pressure plate on the shearing workbench,

which is adjusted according to the thickness of the sheared

workpiece. There is adjustable dog plate on the workbench

for the positioning of shearing. The dog plate can be

adjusted by whatever inclination. By its side positioning,

flat steel or angle steel can be sheared at any inclination.

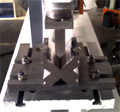

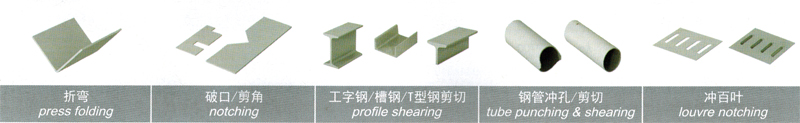

Integrated tool set is used, on its top there are four

stations to make angle steel shearing, round steel and

rectangular steel shearing, flat steel shearing and steel

plate die shearing. If other dies are replaced on the

shearing stations of round steel and round steel, groove

steel and joist steel shearing is also feasible. The tool

set and oil cylinder are linked by hinge, and the upper

end of the oil cylinder is hinged to the body, so that

under the function of the oil cylinder, the tool set sways

in arc shape, to execute shearing.

|

|

The top blade of die shearing station is fixed on the

tool set, the bottom edge is composed of three blades

which are bolted to the die holder. The die shearing blades

on both sides are adjustable, to ensure correct shearing

clearance. There are side stop plate and stop plate fitted

on the shearing workbench to carry out shearing of the

plate at the correct position. The punch is fixed by locknut

to the lower end of the oil cylinder's piston rod. The

lower die supported in the die holder which is bolted

to the body. When the punch and the lower die are aligned,

tighten the bolt. To die-cut rectangular hole and oblong

hole, besides the lateral plane orientation of the piston

rod, oblong locating slod is milled on the heel block

which has external thread. To avoid back swing of the

punch, if other dies are installed in this station, bending,

pipe die shearing, shutters punching, punching large holes

and piercing of groove steel, joist steel and web plate

are also feasible. Operative norm GB/T54373-1994. |

|