|

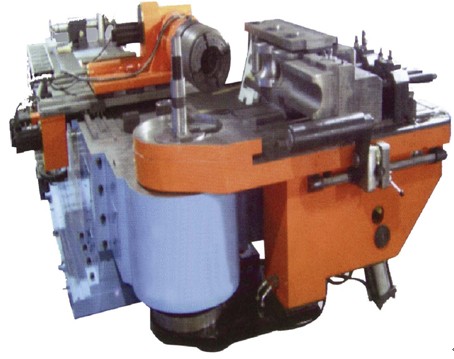

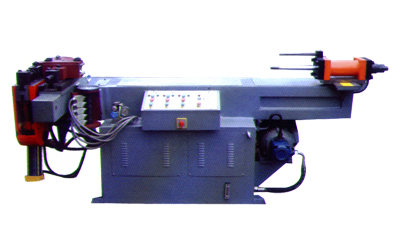

W27YPC

Micro-computer Hydraulic Pipe-bending

Machine

|

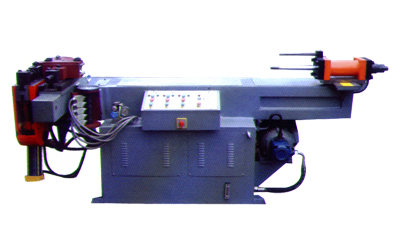

W28KThree-coordinate

Three-dimensional Pipe-bending

|

|

|

|

|

| Reinforcing

rib design for the hand-piece and body of the

machine tool, and interior stress is eliminated

through annealing treatment. Overall, it has enough

strength and rigidity to avoid permanent deformation.

When fitting the transmission main shaft, it's

inserted from top of the head-piece, the installation

is accurate and maintenance is convenient. The

principal axis of bending pipe and the drive sprocket

go through solid forging, gear hobbing and non-key

connection, it's stressed evenly and driven by

double oil cylinder. Before the tumbler approaches

the angle value set by bending, the hydraulic

system automatically throttles and buffers. The

bending precision is significantly improved. There

is throttling buffer set when fast reposition

reaches the starting point, thus greatly improving

reposition precision and work efficiency (we are

the only producer in domestic China using this

structure). The clamp system uses sinking-mode

four-bar linkage lifting force-amplifier. After

bending the finished product, the chuck sinks

into tumbler, making it easier for loading and

unloading and space tube bending (the finished

product naturally falls under gravity, pipe discharge

convenient). Micro-computer controller can pre-set

16 bending angles, and the whole process flow

can be completed at one time by the foot switch:

hydraulic tightening, hydraulic pressing, hydraulic

bending, hydraulic auxiliary driving and drawing-core,

including special accessory crapiness proof unit.

Six oil cylinders (feeding vehicles and space

bending angle functions can be added). |

|

Product

Name, Parameters

|

W27YPC

Micro-computer Hydraulic Pipe-bending

Machine

|

|

W28K

Three-coordinate Three-Dimensional Pipe-bending

Machine

|

|

60

|

76

|

89

|

114

|

121

|

168

|

219

|

273

|

325

|

402

|

|

Maximum

pipe-bending specifications

|

mm

|

Φ60*5

|

Φ76*6

|

Φ89*8

|

Φ114*8

|

Φ121*8

|

Φ160*14

|

Φ219*16

|

Φ273*18

|

Φ325*20

|

Φ402*25

|

|

Pipe

Yield Limit

|

mpa

|

|

|

|

|

|

≤245

|

≤245

|

≤245

|

≤245

|

≤245

|

|

Minimum

Pipe-bending specifications

|

mm

|

Φ10

|

Φ15

|

Φ20

|

Φ30

|

Φ30

|

Φ60

|

Φ76

|

Φ89

|

Φ114

|

Φ159

|

|

Maximum

bending radius

|

mm

|

R300

|

R400

|

R450

|

R550

|

R600

|

R800

|

R1000

|

R1200

|

R1500

|

R1800

|

|

Minimum

bending radius

|

mm

|

R50

|

R60

|

R80

|

R100

|

R150

|

R200

|

R250

|

R300

|

R350

|

R400

|

|

Standard

core bar length

|

mm

|

2500

|

3000

|

4000

|

5000

|

6000

|

6000

|

8000

|

9000

|

10000

|

12000

|

|

Maximum

bending angle

|

°

|

195

|

195

|

195

|

195

|

195

|

195

|

195

|

195

|

195

|

195

|

|

Bending

Speed (Axle B)

|

r/min

|

3

|

2.6

|

2.0

|

1.25

|

1.1

|

0.72

|

0.45

|

0.3

|

0.2

|

0.1

|

|

Return

Speed

|

r/min

|

4

|

5

|

4

|

3.2

|

2.9

|

2.2

|

1.8

|

1.4

|

1.2

|

1.0

|

|

Small

Car

|

Feeding speed

(Axle Z) m/min |

0-30

|

0-30

|

0-30

|

0-25

|

0-25

|

0-20

|

0-20

|

0-10

|

0-10

|

0-10

|

|

Roll

Speed (Axle C) r/min

|

0-20

|

0-20

|

0-15

|

0-10

|

0-10

|

0-8

|

0-6

|

0-4

|

0-2

|

0-2

|

|

Machine

weight

Complex precision

|

Axles

B and C

|

°

|

±0.1

|

±0.1

|

±0.1

|

±0.1

|

±0.1

|

±0.1

|

±0.1

|

±0.2

|

±0.2

|

±0.2

|

|

Axle

Z

|

mm

|

±0.1

|

±0.1

|

±0.1

|

±0.1

|

±0.1

|

±0.2

|

±0.3

|

±0.4

|

±0.5

|

±0.8

|

|

Hydraulic

System Work Pressure

|

mpa

|

≤8

|

≤12

|

≤12

|

≤14

|

≤16

|

≤16

|

≤18

|

≤20

|

≤25

|

≤25

|

|

Oil

pump rated pressure

|

mpa

|

12

|

16

|

16

|

21

|

21

|

21

|

25

|

25

|

25

|

25

|

|

Oil

pump motor power

|

KW

|

5.5

|

7.5

|

11

|

15

|

18.5

|

22

|

30

|

45

|

55

|

75

|

|

Machine

overall dimensions (Length*width*height)

|

m

|

3*1.2

*1.1

|

4*1.5

*1.2

|

5.5*1.7

*1.3

|

6*1.8

*1.5

|

7*1.9

*1.5

|

8*2.1

*1.6

|

9.5*2.2

*1.8

|

11*2.5

*2

|

12*2.9

*2.2

|

14*3.5

*2.5

|

|

Machine

Weight

|

kg

|

1400

|

2000

|

4000

|

5000

|

6000

|

15000

|

20000

|

26000

|

32000

|

40000

|

|

...................................................................................................

|

|

| This is

cold pipe-bending machine, a molding equipment

which bends the pipe by using core rod or

not using core rod under room temperature

without adding any loading. It can bend

various plane pipe and space pipe. After

replacing mold, it can also bend various

round steel, angle steel and groove steel.

It's applicable to industries such as ship

manufacture, boiler, petroleum, chemical,

aviation, metal structure and machinery

manufacture. It is fully hydraulic drive,

each action is integrally controlled by

electric. The whole machine structure is

reasonable and performance is reliable,

flexible to operate, convenient to maintain,

an ideal equipment for bending forming of

metal pipes and shapes. |

|

W27Y-159*14

|

|

Machine

Model

|

Unit

|

W27Y-159*14

|

W27Y-219*8

|

Y27Y-219*18

|

|

Maximum

Bending Pipe (diameter*wall thickness)

|

mm

|

159*14

|

219*8

|

219*18

|

|

Pipe

Yield Limit

|

mpa

|

≤245

|

≤245

|

≤245

|

|

Maximum

Bending Angle

|

o

|

195

|

195

|

195

|

|

Minimum

Diameter of Maximum Specifications Pipe

|

mm

|

480

|

650

|

660

|

|

Bending

radius range

|

mm

|

250-800

|

250-800

|

400-1000

|

|

Clamp

splice and trolley stroke

|

mm

|

180

|

180

|

250

|

|

Bending

speed

|

r/min

|

0.4

|

0.4

|

0.5-0.85

|

|

Return

Speed

|

r/min

|

0.37

|

0.37

|

1-2

|

|

Standard

core rod length

|

mm

|

4500

|

4500

|

6000

|

|

Core

rod oil cylinder stroke

|

mm

|

320

|

45

|

45

|

|

Hydraulic

system work pressure

|

mpa

|

14(140)

|

14(140)

|

26.5(265)

|

|

Oil

Pump

|

Model

|

Type

|

CB-H50C-FL

|

CB-H50C-FL

|

63SCY14-1

|

|

Pressure

|

mpa

|

14(140)

|

14(140)

|

32(320)

|

|

Flow

|

L/min

|

73.5

|

73.5

|

9.2

|

|

Motor

|

Model

|

Type

|

Y180L-4

|

Y180L-4

|

J03-L-200M-4

|

|

Power

|

kw

|

22

|

22

|

40

|

|

Rotate

Speed

|

r/min

|

1470

|

1470

|

1470

|

|

Overall

Dimensions (length*width*height)

|

mm

|

6150*2400*1520

|

6300*2400*1640

|

9856*4590*1660

|

|

Machine

Weight

|

kg

|

13500

|

14000

|

26590

|

|

...................................................................................................

|

|

W27Y-60A

|

| W27Y-60A

pipe-bending machine is one of the products introduced

by us from Germany in the 80s. The most important

feature of this machine is that the tumbler is cast

inblock and wholly processed. Institutional clip

pipe is added to the sinking four linkage pipes.

Cam locating and automatic pipe bending. After the

product is finished, the chuck automatically loosens

to sink, and naturally falls under gravity. Hydraulic

clamp pipe, hydraulic pressing and hydraulic core

drawing. There is mechanical amplification angle

indicator gauge. Four angles can be pre-set (4 different

angles can be bended consecutively on the same pipe).

Products Germanized are stable and reliable. Before

leaving our factory, the machine shall operate for

ten continuous hours, and it won't be delivered

until there is no problem with it. |

|

Name

|

Value

|

Unit

|

Remarks

|

|

Maximum

pipe bending Ability

|

Φ60X5

|

mm

|

A3

|

|

Maximum

Bending Radius

|

300

|

mm

|

Can

be elongated

|

|

Minimum

Bending Radius

|

10

|

mm

|

|

|

Main

Motor Power

|

5.5

|

kw

|

960r/mm

|

|

Machine

Weight

|

1500

|

kg

|

约

|

|

|

| ................................................................................................................. |

|

Pipe-bending

Machine Molds and Accessories

|

|

|

|

|

|

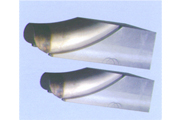

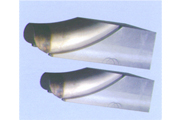

Crease-resist

Block

|

Crease-resist

Block

|

Special

Supply Materials

|

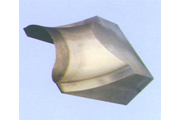

Pipe-bending

Die

|

|

|

|

|